Lead is a malleable, blue-gray, heavy metal that occurs naturally in the environment. Lead is found in many forms and can be hazardous when inhaled as a dust or fume, or accidentally ingested after contact directly or with contaminated surfaces.

While inorganic lead does not readily enter the body through the skin, it can enter the body through accidental ingestion (eating, drinking, and smoking) via contaminated hands, clothing, and surfaces.

Health effects of lead

Exposure to lead, especially at elevated levels for extended periods of time, can cause adverse health effects. Children are especially vulnerable to the health effects of lead. Health effects include neurological (e.g., memory and concentration problems) and gastrointestinal (i.e., digestive problems). Lead can also affect the reproductive system, blood (including causing anemia), kidneys, and cause muscle and joint pain.

Before using lead-containing materials, investigate alternatives to using lead or changing a process to avoid its use.

Safety precautions

Lead is highly regulated; its use and presence are managed to ensure the lowest potential exposure.

Safety precautions for the specific types of lead commonly used at the UW are provided below and detailed throughout the UW Lead Safety Program Manual and in the EH&S focus sheets referenced in the sections below.

Lead in building materials

The most common lead-containing material in buildings is lead-containing paint in older buildings built before 1978. Other lead-containing building materials may include: roofing and pipework; solder in plumbing and electrical equipment and systems; mortar in brick and stonework in older buildings; glazing and leaded glass.

Procedures must be in place to monitor its condition and address the following:

- Inform building managers and occupants of the presence of lead-containing paint (pictured) and other lead-containing building materials; and to not disturb it, and report if damaged.

- Manage construction and maintenance activities so that work does not cause lead exposures to workers doing the work or building occupants.

- Conduct lead abatement projects according to regulations and inform building occupants.

Review the EH&S Lead in Building Materials Focus Sheet for more information.

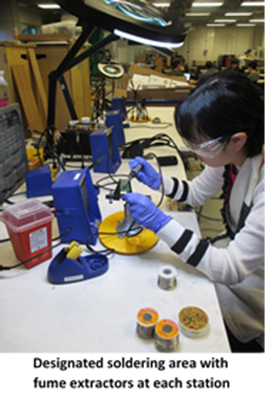

Lead in products/chemicals in shops and labs

Shops, makerspaces and labs may use lead-containing products such as solder (pictured), or work with lead-containing chemicals or items in their research or academic work. Common lead-containing chemicals used in UW labs in small quantities include lead acetate, lead oxide, lead chloride, lead iodide, lead nitrate and lead metal.

Shops, makerspaces and labs are required to register lead products/chemicals in the MyChem inventory and submit a Safety Data Sheet (SDS).

Review the EH&S Lead Safety in Shops and Labs for more information.

Metallic lead

Metallic lead is used in many different forms including bricks (pictured), sheeting, plates, shot, and weights. The lead materials can be pure lead (99.9% or greater) or be an alloy with other metals.

Researchers, medical personnel, scuba divers and others who use metallic lead as shielding for radiation sources, weights and other applications are required to register the metallic lead in the MyChem inventory and submit an SDS.

Metallic lead is used in many different forms including bricks, sheeting, plates, shot, and weights.

Review the EH&S focus sheets Metallic Lead Safety and Lead Safety for Scuba Divers for more information.

Incident reporting

UW personnel are required to submit an incident report to Environmental Health & Safety for any work-related event that results in an injury, illness, exposure to hazardous materials, or fire, regardless of the work location.

UW personnel are highly encouraged to submit work-related near-miss events. Visit the Incident Reporting page for more information.